| |

001.

Basic functions of the piston rings

Basic functions of the piston rings

- Air

Density Functions: To avoid air leaking from the top of the piston

- Thermal

Conduction: Guiding the heat produced by the explosion via the

piston rings to the wall of the cylinder in order to disperse

heat.

- Lubricate

and scrape oil: Restrict excess oil in entering the chamber and

also aids in lubrication of the cylinder wall.

- Maintaining

the operation of the piston

002.

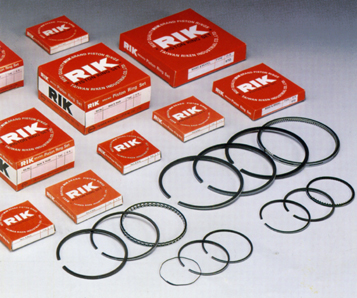

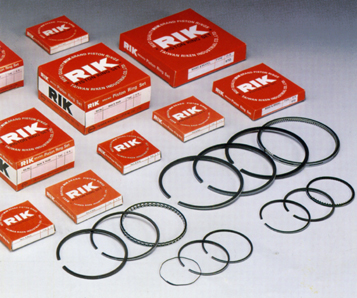

The right piston rings for your engine

The right piston rings for your engine

As

compared to the size of an engine, the piston ring is relatively

small. Thus, generating a misleading concept of its importance.

In fact, the role of the piston rings impersonates the valve in

a heart. Inappropriate use will lead to high consumption of the

engine oil, scraping of the cylinder wall, reduced horsepower, increased

usage of petrol, increased noise pollution etc.

Due to the limited expertise and knowledge, a lot of smaller competitions

come up with products that are inferior in its outlook. Under close

examination, some minor characteristics of the piston rings are

inferior and go against the principal of the design; after the usage

of such products will lower the performance of the engine and cause

extreme damage to the engine.

By choosing RIKEN products, a world class and professional manufacturer

brand, will guarantee the quality of the piston rings, the only

way to enhance the life of an engine.

003.

Meaning behind the engravings

Meaning behind the engravings

There

are two functions to the engraving on the side of the piston ring,

one is to point out the direction of the piston ring and the other

is to identify the size, the allocated space of the piston ring

and the manufacturing factory.

Due to its design, the piston rings must be installed appropriately

with the engravings on top. If not, it will not perform at its best;

on the contrary, it will cause severe damage to the cylinder.

The engravings on the right side of the piston ring is normally

used to distinguish the factory that produces it, For example, "R"

stands for Taiwan Riken Factory, "R1" and"R2"

stands for the placement of the pistons rings or "RN"

meaning the material used to manufacture RIK-20.

The engravings on the left of the piston ring indicates information

on the size of the outer diameter, if it has been enlarged. The

markings are as shown:

| Engraved

Markings |

Enlarged

Exterior Diameter |

Engraved

Markings |

Enlarged

Exterior Diameter |

| Without

Engraved Markings |

0.00mm |

100 |

1.00mm |

| 25 |

0.25mm |

150 |

1.50mm |

| 50 |

0.50mm |

200 |

2.00mm |

| 75 |

0.75mm |

250 |

2.50mm |

004.

Important points for assembling piston rings

Important points for assembling piston rings

- The

piston rings need to be cleaned before installation and specific

tools are needed to install the piston rings.

- Start

the assembly from the bottom of the ditch, always ensuring that

the engravings are facing the top.

- Each

piston ring needs to be separated (avoid forming a straight line)

about 15 degree, and avoid the aperture in a 90 degree position.

- Notice

of the Steel Vent Assembly

4-1. Firstly place the spacer in

the ditch, ensuring that the pointed part is facing the top of

the piston ring and prohibited to overlap around.

4-2. Install 2 pieces of rail, ensuring

that the connecting part is about 15 degree apart.

4-3. After installation, ensure that

you are able to rotate the piston ring smoothly.

- When

installing piston rings with Coil or Expander, make sure that

the connecting points are 180 degree apart.

|

|